Super Purity Acids and Reagents

Super Purity Performance at a Reasonable Cost

Today's users of pure acids and reagents in trace inorganic analysis well understand the importance of minimal background impurities.

And with environmental issues at the forefront of current analytical requirements they acknowledge the need to seek ever decreasing levels of contaminats. For them, ROMIL‑SpA™ Super Purity Acids and Reagents provide a practical solution by combining very high purity with a reasonable price.

Available are the major mineral acids; nitric*, hydrochloric*, hydrofluoric*, sulphuric*, percholoric* as well as acetic acid*, ammonia solution*, hydrogen peroxide and water.

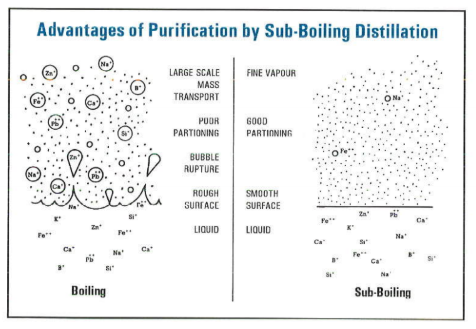

Whereas other reagent suppliers simply batch select or distil their acids by traditional boiling, ROMIL-SpA™ Super Purity Acids are purified by sub-boiling distillation.

But What is it that's so special about this technique that it imparts a greater purity to the finished product than traditional methods? Just look at the diagram. The secret lies in the smooth surface and fine vapour that is maintained over the liquid surface at a temperature just below the boiling point. This avoids the violent agitation and large scale mass transfer of contaminants that is inevitable with conventional distillation.

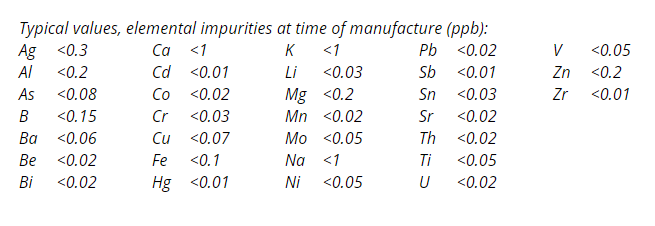

Remaining metallic impurities after sub-boiling distillation are generally in the region of less than 0.1-1 ppb and are confirmed by rigorous testing of each batch. To maintain these low levels most of the ROMIL-SpA™ products are packaged in pre-cleaned polyethylene bottles (pre-cleaned glass bottles for percholoric acid).

Whether the instrumental application is atomic spectroscopy (AAS, GFAAS, ICP‑OES, ICP‑MS), ion chromatography or voltammetry, ROMIL-SpA™ products are the ideal tools for today's routine inorganic trace analysis.

Key applications overview

Inductively Coupled Plasma (ICP-OES, ICP-MS)

With key metal concentrations below 1 ppb, ROMIL-SpA™ acids are an economical solution to sample preparation in high throughput qc analysis. For the most demanding applications we recommend the use of ROMIL-UpA™ products where metal concentrations are controlled to ppt levels - like a leaf in a forest.

Atomic Absorption (AAS, GFAAS)

Whilst now overshadowed by faster and more sensitive ICP techniques, atomic absorption spectrometry is still the main tool for trace metal determinations in many smaller analytical laboraories. Use of ROMIL-SpA™ acids in sample preparation contributes to trouble-free analysis thus ensuring the continued popularity of this relatively simple technique for many years to come.

Ion Chromatography (IC)

Although now a well established technique, ion chromatography never really caught on in the analysis of metals due to the popularity of the spectrometric techniques. In analysis of anions, however, ion chromatography reigns supreme. The same purification techniques that control metal ions in ROMIL-SpA™ acids also have the same effect on anionic species which means that sample preparation can be undertaken free from otherwise interfering background impurities.

Voltammetry

Also known in the past as polarography, this technique remains popular as a low capital cost entry into trace analysis. Sensitivity is similar to that for ICP with the further advantage that different oxidation states of elements can be identified. Not only can metal ions be determined but also some anions and organic compounds. Samples with high ionic concentration are also not a problem for voltammetry. With the availablity of ROMIL-SpA™ products for sample preparation, this technique continues to see an increase in popularity.

Analysis Method

Most elements are determined by high resolution ICP‑MS using sample preconcentration. The results are an average of three aliquots subsampled from three samples representative of the batch. The samples are slowly evaporated to dryness. The resulting residue is reconstituted in a small volume of 2% Nitric Acid / 2% Hydrogen Peroxide ROMIL‑UpA. Operations are conducted under Class 100 or better clean-room conditions. For volatile elements (eg, Hg), the acid samples are diluted then directly injected into the ICP‑MS. Values below 3 times the standard deviation of the blank are shown with '<', no blank value is subtracted.

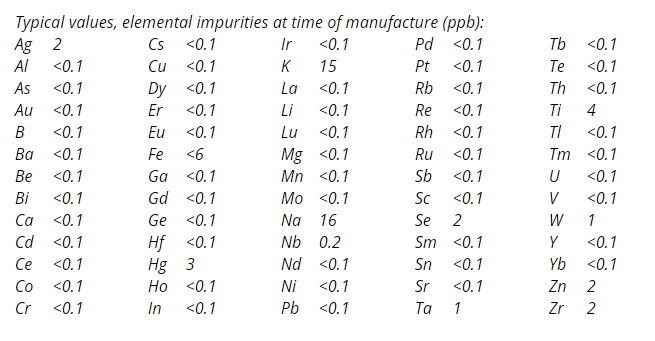

Acetic Acid SpA

H015

500ml 2½LT (HDPE) : (Acetic Acid glacial)

Dgr H:226-314 : CH3COOH MW 60.05 FP 16.7°C BP 117.9°C d 1.05 CAS [64-19-7]

P:280c-301+330+331-305+351+338- : Assay >99%

307+310 : Colour <10 Hazen (APHA)

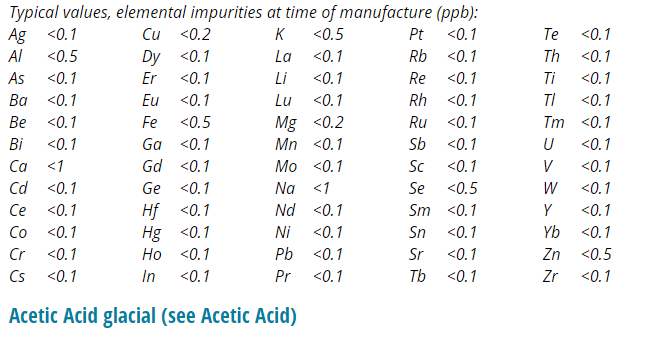

Be, Bi, Ce, Co, Cs, Dy, Er, Eu, Ga, Gd, Hf, Ho, In, La, Li, Lu, Nd, Pb, Pr, Rb, Re, Sc, Sm, Tb, Th, Tl, Tm, U, Y, Yb, Zr <0.1 ppb each

As, Ba, Cd, Cu, Ge, Mg, Mn, Mo, Ni, Pt, Rh, Ru, Sb, Sn, Sr, Te, Ti, V, W <0.5 ppb each Ag, Al, Ca, Cr, Fe, Hg, K, Na, Se, Zn <1 ppb each

SO4 <0.5 pp

PO4 <1 ppm

Cl <1 ppm

Substances reducing dichromate passes test

Substances reducing permanganate passes test

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis (for organic trace analysis see ROMIL Code H014 Acetic Acid SpS), Ion Chromatography, Voltammetry

Elemental impurities specified at time of manufacture.

Ammonia solution SpA

H058

500ml (HDPE) : (Ammonium Hydroxide solution)

Dgr H:314-335 NH3 MW 17.03 d 0.92 CAS [1336-21-6]

P:280c-301+330+331-304+340- Assay 20-22%

305+351+338-309+310 Colour <10 Hazen (APHA)

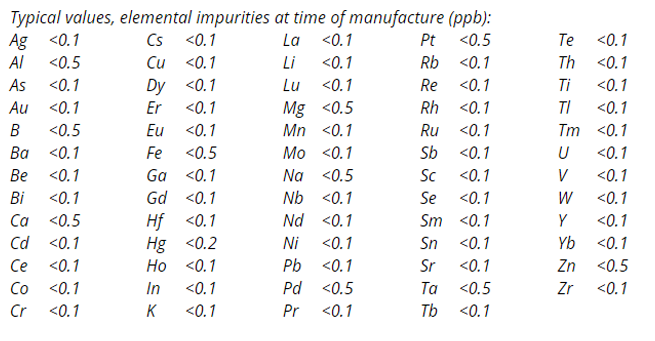

Ba, Be, Bi, Ce, Cs, Dy, Er, Eu, Ga, Gd, Ge, Ho, In, La, Li, Lu, Nb, Nd, Pb, Pr, Rb, Sc, Sm, Sr, Tb, Te, Th, Tl, Tm, U, W, Y, Yb, Zr <0.1 ppb each

Hg <0.2 ppb

Ag, Au, Cd, Co, Cr, Cu, Mn, Mo, Ni, Rh, Sb, Sn, Ti, V, Zn <0.5 ppb each

Al, As, Ca, Fe, K, Mg, Na, Se <1 ppb each

PO4 <0.01 ppm

Cl <0.5 ppm

SO4 <1 ppm

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis, Ion Chromatography, Voltammetry

Elemental impurities specified at time of manufacture

Hydrochloric Acid SpA

H396

500ml 2½LT (HDPE) : HCl MW 36.46 d 1.18 CAS [7647-01-0

Dgr H:290-314-335 : Assay 34-37%

P:280c-301+330+331-305+351+338- Colour <10 Hazen (APHA)

309+310 : Ba, Be, Bi, Cd, Ce, Co, Cs, Dy, Er, Eu, Ga, Gd, Hf, Ho, In, La, Li, Lu, Mn, Mo, Nb, Nd, Pb, Pr, Rb, Re, Rh, Ru, Sc, Sm, Sr, Tb, Te, Th, Tl, Tm, U, W, Y, Yb, Zr <0.1 ppb each

As, Au, Cr, Cu, Hg, Mg, Ni, Sb, Sn, Ti, V <0.5 ppb each

Ag, Al, B, Ca, Fe, K, Na, Se, Zn <1 ppb each

Total P <0.01 ppm

Total S <0.3 ppm

Free Cl2 <0.5 ppm

Br <10 ppm

Substances reducing permanganate passes test

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis, Ion Chromatography, Voltammetry

Elemental impurities specified at time of manufacture.

Hydrofluoric Acid SpAs

H058

500ml (LDPE) : HF MW 20.01 d 1.16 CAS [7664-39-3]

Dgr H:300+310+330-314 : Assay 47-51%

P:280-301+330+331-302+352-304+340- : Colour <10 Hazen (APHA)

305+351+338-309+310+ROP010 : Ba, Be, Bi, Cd, Ce, Co, Cs, Dy, Er, Eu, Ga, Gd, Ge, Hf, Ho, In, La, Li, Lu, Mn, Mo, Nb, Nd, Pb, Pr, Rb, Re, Rh, Ru, Sc, Sm, Sr, Tb, Te, Th, Tl, Tm, U, V, Y, Yb, Zr <0.1 ppb each

Au, Pd, Pt, Sb <0.2 ppb each

Ag, As, Cu, Ni, Sn, W <0.5 ppb each

Al, B, Ca, Cr, Fe, Hg, K, Mg, Na, Se, Ti, Zn <1 ppb each

Total P <0.05 ppm

Total S <0.1 ppm

Cl <4 ppm

SiF6 <20 ppm

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis, Ion Chromatography, Voltammetry

Elemental impurities specified at time of manufacture

For treatment of HF burns, calcium gluconate gel (ROMIL Code PCG9V) is recommended. In order to provide emergency first aid, it should be kept wherever HF is handled or stored.

Hydrogen Peroxide SpA

H416

500ml (HDPE) : H2O2 MW 34.01 d 1.10 CAS [7722-84-1]

Dgr H:302-318 : Assay ca. 30%

P:280e-305+351+338-313 : Colour <10 Hazen (APHA)

B, Be, Bi, Ce, Co, Cs, Dy, Er, Eu, Ga, Gd, Ge, Hf, Ho, In, Ir, La, Li, Lu, Mn, Mo, Nd, Ni, Pd, Pt, Rb, Re, Rh, Ru, Sb, Sc, Sm, Sn, Sr, Tb, Te, Th, Tl, Tm, U, Y, Yb <0.5 ppb each

As, Ba, Cu, Cr <1 ppb each

Ag, Al, Cd, Hg, Mg, Pb, Se, Ta, V, Zr <5 ppb each

Ti, W, Zn <10 ppb each

Au, Ca, Fe, K, Na, Nb <50 ppb each

Cl, PO4 <0.5 ppm each

SO4, NO3 <1 ppm each

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis, Ion Chromatography, Voltammetry

Elemental impurities specified at time of manufacture

As a safety measure we fit bottles with a closure featuring a venting valve.

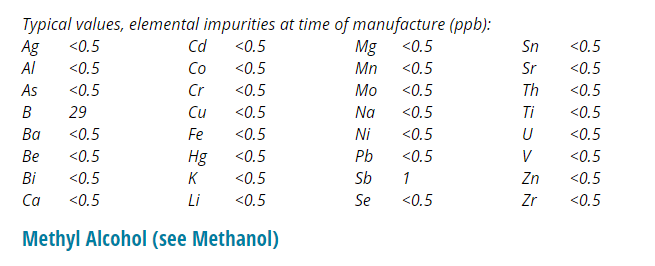

Methanol SpA / low metals

H413

500ml 1LT 2½LT (HDPE) : (Methyl Alcohol)

Dgr H:225-301+311+331-370 : CH3OH MW 32.04 BP 64.5°C d 0.79 CAS [67-56-1]

P:210-280f-302+352-309+310-403+235 : Assay >99.9% Water <0.03% Residue <0.0001%

Group 1 & 2 elements typically <0.5 ppb

Group 3 to 12 (transition) elements typically <0.5 ppb

Group 13, 14, 15 elements typically <0.5-<50 ppb

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis (for organic analysis and chromatography see ROMIL Code H410 Methanol SpS)

Methyl iso-Butyl Ketone SpA

H439

500ml 2½LT (HDPE) : (4-Methylpentan-2-one)

Dgr H:225-332-319-335-EUH066 : (CH3)2CHCH2COCH3 MW 100.16 BP 117.4°C d 0.80 CAS [108-10-1]

P:210-305+351+338-304+340 : Assay >99.8% Water <0.01% Residue <0.0001%

Group 1 & 2 elements typically <0.1-<250 ppb

Group 3 to 12 (transition) elements typically <0.1-<100

Group 13, 14, 15 elements typically <0.5-<100 ppb

Peroxides (at time of manufacture) <0.0001% (<1 ppm)

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis (for organic analysis and chromatography see ROMIL Code H446 Methyl iso-Butyl Ketone SpS)

4-Methylpentan-2-one (see Methyl iso-Butyl Ketone)

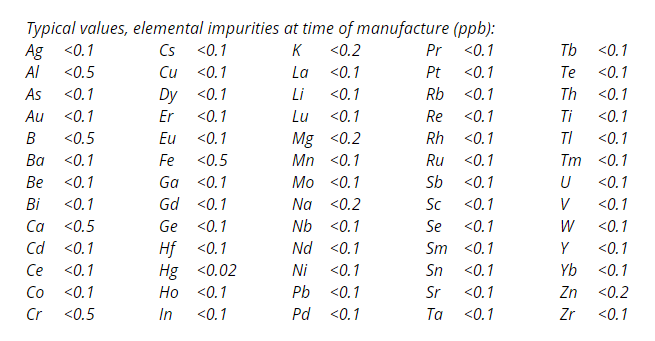

Nitric Acid SpA

H566

500ml 1LT 2½LT (HDPE) : HNO3 MW 63.01 d 1.42 CAS [7697-37-2]

Dgr H:272-290-314-EUH071 : Assay 67-69%

P:260c-280c-301+330+331- : Colour <10 Hazen (APHA)

305+351+338-309+310 : Ag, Au, Ba, Be, Bi, Ce, Cs, Dy, Er, Eu, Ga, Gd, Ge, Hf, Hg, Ho, In, La, Li, Lu, Mn, Mo, Nb, Nd, Pb, Pr, Rb, Re, Sc, Sm, Sr, Tb, Te, Th, Tl, Tm, U, W, Y, Yb, Zr <0.1 ppb each

As, Cd, Co, Cu, Ni, Pd, Pt, Rh, Ru, Sb, Sn, Ti, V, Zn <0.5 ppb each

Al, B, Ca, Cr, Fe, K, Mg, Na, Se <1 ppb each

Total P <0.01 ppm

Cl <0.2 p

Total S <0.3 ppm

Store in dark.

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis, Ion Chromatography, Voltammetry

Elemental impurities specified at time of manufacture

Concentrated Nitric Acid can decompose to nitrogen oxides (NOx) through action of heat or light resulting in a yellow colouration. However, this does not affect the performance of the acid with respect to trace metals or oxidising power. Storage in a cool, dark place is recommended.

Perchloric Acid SpA

H584

500ml 2½LT (HDPE) : HClO4 MW 100.46 d 1.66 CAS [7601-90-3]

Dgr H:271-290-314 : Assay 65-71%

P:210-221-280c-301+330+331- : Colour <10 Hazen (APHA)

305+351+338-309+310 : As, Au, Be, Bi, Ce, Co, Cs, Cu, Dy, Er, Eu, Ga, Gd, Ho, In, La, Li, Lu, Mo, Nd, Pd, Pr, Pt, Rb, Rh, Sb, Sc, Sm, Sr, Tb, Te, Tl, Tm, U, V, Y, Yb, Zr <0.5 ppb each

Ag, Al, Ba, Ca, Cd, Fe, K, Mg, Mn, Na, Ni, Pb, Sn, Th, Ti, Zn <1 ppb each

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis, Ion Chromatography, Voltammetry)

Elemental impurities specified at time of manufacture.

Perchloric Acid SpA / less than 50% w/w

H675

500ml 2½LT (HDPE) : HClO4 MW 100.46 d 1.40 CAS [7601-90-3]

Dgr H:271-314 : Assay 46-49%

P:220o-280c-305+351+338-310 : Colour <10 Hazen (APH

As, Au, Be, Bi, Ce, Co, Cs, Cu, Dy, Er, Eu, Ga, Gd, Ho, In, La, Li, Lu, Mo, Nd, Pd, Pr, Pt, Rb, Rh, Sb, Sc, Sm, Sr, Tb, Te, Tl, Tm, U, V, Y, Yb, Zr <0.5 ppb each

Ag, Al, Ba, Ca, Cd, Fe, K, Mg, Mn, Na, Ni, Pb, Sn, Th, Ti, Zn <1 ppb each

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis, Ion Chromatography, Voltammetry

Elemental impurities specified at time of manufacture.

Less hazardous acid concentration to facilitate international shipping.

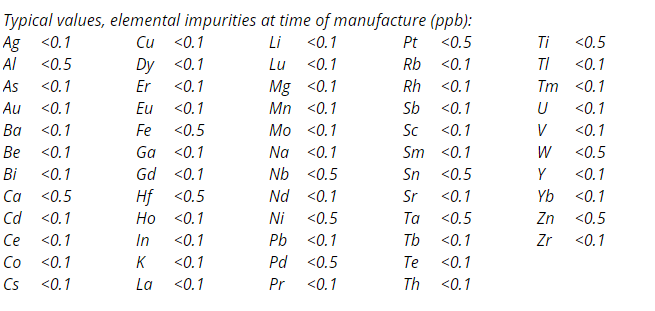

Sulphuric Acid SpA

H691

500ml 1LT 2½LT (HDPE) : H2SO4 MW 98.07 d 1.84 CAS [7664-93-9]

Dgr H:290-314 : Assay 93-98%

P:280c-301+330+331-305+351+338- : Colour <10 Hazen (APHA)

309+310 : Ba, Be, Bi, Dy, Er, Eu, Ga, Gd, Hf, Ho, La, Lu, Nd, Pb, Pr, Sc, Sm, Tb, Te, Th, Tm, U <0.1 ppb each

Au, Cd, Ce, Co, Cr, Cs, Cu, In, Li, Mn, Mo, Nb, Ni, Pt, Rb, Rh, Sr, Tl, V, W, Y, Yb, Zr <0.5 ppb each

Ag, Al, As, Ca, Fe, Ge, Hg, K, Mg, Na, Sb, Sn, Ti, Zn <1 ppb each

Se <10 ppb

Total P <0.05 ppm

NO3 <0.2 ppm

Cl <0.7 ppm

Substances reducing permanganate <20 ppm

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis, Ion Chromatography, Voltammetry

Elemental impurities specified at time of manufacture.

Water SpA

H951

2½LT (HDPE) : H2O MW 18.02 FP 0.0°C BP 100.0°C CAS [7732-18-5]

Residue <0.0001%

Resistivity (at time of manufacture) >18 MOhm @ 25°C

Elemental impurities at time of manufacture:

Ag, Ba, Be, Bi, Cd, Hg, Mo, Pb, Sb <0.5 ppb each

Al, As, B, Co, Cr, Cu, Li, Mn, Ni, Sn, Sr, Th, Ti, U, V, Zr <1 ppb each

Fe, Mg, Zn <2 ppb each

Ca, K, Na <20 ppb each

Equivalent to ASTM D1193 Type II

Cl <4 ppm

SiF6 <20 ppm

Application: Environment Analysis (eg, using AAS, ICP-OES, ICP-MS), Trace Metal Analysis (for HPLC and organic trace analysis see ROMIL Code H950 Water SpS), Ion Chromatography, Voltammetry